MICHAEL REVYAGIN PIPES

Michael´s Web-Site

Michael Revyagin was born in Grosny (Chechenya) in 1972. In 1992 Moscow and Grosny floated on the edge of a war. Because of the dangerous situation and because he has found his companion through life at that time, Revyagin left the town of his happy childhood. He has fled to Russia and lost all belongings as well as the flat. He was forced to go into the Russian cloudy business waters of the 1990 years. The result was a little flat near Moscow which he could buy in 1997. He lives here to this day.

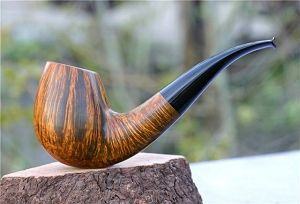

A great Ramses by Michael Revyagin

The first pipe shops were opened in Moscow at that time. Of course Reyagin has immediately bought a pipe for himself. This was a dream for child years because his favourite hero was Huckleberry Finn. He became a pipe smoker. When smoking pipe comfortably he began to think about his future. He was not interested simply to earn money in a regular, boring job. He had an own flat and all what was necessary for the life and all other things. The solution lay availably close like it is often happens.

If one smokes a pipe, of course it happens, that it breaks. And Revyagin has carried out the first repairs personally and he has enjoyed this job. He has decided to make advertising into the pipe shops for stem repairs what was quite a good school . After two years of repairs he took the decision only to make pipes in future. Only to make pipes, neither to make any repairs, nor other side jobs. It was exciting to understand the secrets of pipe making independently, to collect the information step by step and to develop a style of his own.

Michael Revyagin starts to make pipes in 2000. His basic concepts are: Each of his pipes is hand made and free hand drilled. His second principle is making neither rustic nor sand-blasted pipes because he is fan of high-quality Briar. He uses Vulcanite from Germany and for the ornamentations mammoth ivory, acryl and titanium are used. His third principle is: The pipes are not subject to any graduation. Every graduation is said for him to demote himself as an artist.

All processing steps are always made by hand, the shape first and then drilling tobacco chamber, channel and mortise. This procedure is optimally to fit grain and shape, it is the more creative way, but anyway considerably time consumptive than the machine processing.

To start with the machine-assisted drilling reduces the degrees of freedom shapewise but may be the right way for factory made pipes. This would indicate for Revyagin to tie up his own imagination. "How a heathen the amazing grain of briar idolizes me. This beauty causes my enthusiasm. The enchanting grain was the reason to make only smooth pipes during the last couple of years ", he wrote.

In his opinion, blasting of a pipe is only reducing the risk, but the risk is a component of his art. He is not sure until the last minute whether the pipe turns out well or not. In this case the briar has the final word. Briar is an artist just as the carver. Both are equal for each other. Revyagin wrotes to this " one can draw a parallel here with the Perfumeur. If he try to compose a new smell, he takes base oils, alcohol and flavour additions which then makes his new perfume unique. I just the same way my pipe based on my skilled crafts and then "drip" a little of my art purely (it is important not to exaggerate), then a little risk comes in and some other nuances. And you think again and again is this well made or not?"

Pictures by Michael Revyagin und Alexey Osokin, with kind permission

Any copying, publication or reproduction of the papers and / or pictures published herein in printed or electronic media is strictly prohibited without the explicit written consent of these pages' owner. (c) Pipendoge, 2009