The History of Danish Pipes

by Jakob Groth (DK) - adapted and

illustrated by Jörg Lehmann

With kind permission

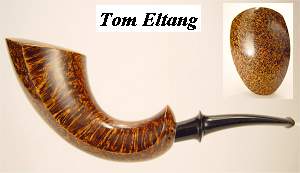

Tom Eltang

Tom Eltang started making pipes in a very young age. Already as a child he was interested in the mysteries of the pipes an interest he inherited from his father. In 1974 at the age of 16 he started as youngest boy by Anne Julie in Vester Voldgade in Copenhagen. He went on the path that coming pipemakers must take: He repaired pipes from morning till dawn for several years. As time went by he was allowed to try him self. After further 3 years of pipe repairing and carving in Pibe-Dan’s work shop, Tom was ready to become independent. First he had to get some of the youth’s need for travelling out of his body. So for one year he sailed around in the Danish seas. Since 1981 Tom has had his own work shop in Taarbaek out side Copenhagen where he also lives with his family. Some times Tom also works as a cabinet maker or carpenter.

The

specialty of Tom is in extreme degree his finish, the so-called laboratory stain.

He learnt this stain to know by Anne Julie, who has also used it, but no one has

perfected this contrasted finish as Tom. Even for Stanwell he has made this

finish on some of the best pipes called Golden Contrast. He also created some of

their shapes in the 90’ties. Tom’s shapes are often very “tight”. Tom

stamps the very best of his pipes (not many)

with a nice little snail.

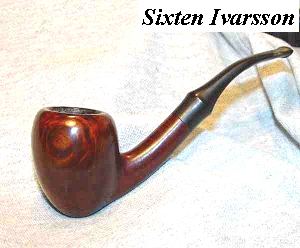

Sixten Ivarsson as Pipe Maker

We have

seen on the importance of Sixten

Ivarsson in general, but here we shall have

a little look on what was special about him besides being the first. Sixten

Ivarsson started, as we know, with new shapes in the end of the 40’ties and

the beginning of the 50’ties. Before that time the shapes were mostly classic.

The few shapes that were not classic were wired and formless. Sixten was the

first to sculpture the bowls making the so called freehand pipe.

To understand what was so new, you have to know a little about the shaping of pipe bowls. There are basically three ways to shape the bowl:

- A copy cutter (?) machine cuts the block of briar after a master which makes a series of exactly the same shapes. This method is traditionally used by pipe factories.

- The pipe bowl is cut or turned on a lathe by the pipemaker. A good pipemaker can make almost (98%) identical shapes. When blocks are turned they will naturally become round shapes (round bowls and shanks). The redundant wood will then be removed with a running band of sandpaper.

- The pipe bowl is shaped in free hand on a ( in Danish called a “bims”), which is a flat, round turning piece of sandpaper on a turning machine and with some kind of vacuum to remove dust. This allows the pipe maker to make unsymmetrical shapes.

This last way of creating and sculpturing pipe bowls was new. And Sixten was the first to really make designed pipes in this way. Several of his unsymmetrical shapes were also produced by Stanwell

Many of his shapes had a “drop” under the bowl, so the bowl looked a little like an egg. In Pipe Dans catalog there was l whole line of different eggs, eg. lapwing’s egg and many others

Another new thing was the technical perfectionism. Today we expect a pipe maker that makes most of the work in hand aim at make exactly the intended shape, perfect drilling, a comfortable bite of the stem, an absolutely smooth surface on the bowl and the stem, a beautiful grain and other technical aspects. But at that time a lot of factory made pipes had more or less imperfection. Sixten sought of lifted up the technical quality. Another specialty of Sixten was his use of different materials like bamboo, horn or even bone from a cow. These materials had been seen before, but in same elegant way. When Sixten started after the war, briar was very much in shortage. So Sixten had to be creative with the blocks. It is said among other pipe makers that when a “normal” pipemaker could make one pipe out of a block of briar, Sixten would make three. To get more bowls out a block, the bowls had to be with rather short shanks and to get a perfect shape, the shanks had to be prolonged with another material.

Sixten was born in 1910. He made his last pipes in 1992-1993. He never had a big production. Not more than ca. 200 pipes per year. He sold his pipes to many countries, Japan, Denmark, Germany and U.S. to name a few. Sixten stopped grading his pipes in 1965.

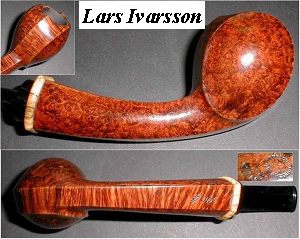

Lars Ivarsson

Lars admits that he has been quite privileged. Very few coming pipe makers have had that chance to earn pocket money as a young boy by repairing broken pipes in the work shop of the leading pipe maker. That is how Lars started the hard way in his father Sixten’s workshop. Already as 17 years old lad he sold his first pipes under his own name to Iwan Ries in Chicago. Lars has won the same high reputation as his father. Before Lars decided to become a pipe maker, he wanted to take a “real” education, so his started to study business economy.

During his studying at the business school he still made a living as a pipe maker. And the pipemaking won over the business economy - even though he took a degree, he never worked as an economist. Like many other pipe makers Lars preferred the peaceful surroundings in the countryside an left Copenhagen to live in a country house where he also has his work shop. The last years that Sixten made pipes Lars assisted him in the work shop one or two days a week. In the mid 80’ties Lars wanted to try his creative skills in another way than only pipemaking, so he started to make his own knives, mostly as a hobby. When you know Lars’ perfection in making pipes you will also know the superb quality of his knives.

The idea of perfection Lars has inherited from his father. Lars says that he remembers how Sixten said “Not good enough” and “keep working” when Lars was young and worked with a detail on a pipe. Today Lars says that you must work on a pipe until you cannot improve it anymore: “Until one more stroke with the sand paper will deteriorate the result.” Lars’ shapes looked quite a lot like Sixten’s in Lars’ young days but he soon found his own style. Lars has created many shapes by sitting with paper and pen and draw - not so much entire pipes, just lines and curves. 15 years ago Lars said he experimented by seeing how curved and compact he could make his pipes. Today his shapes are quite compact or quite long. Half of his pipes are unsymmetrical. His colors for the finish are often brown or reddish.

He makes about 60-70 pipes per year. 1-2 will be stamped with a fish, which is Lars’ symbol for the absolutely best quality. He sells his pipes in Japan, U.S., Swiss and Italy. He smokes Danish produced tobaccos.

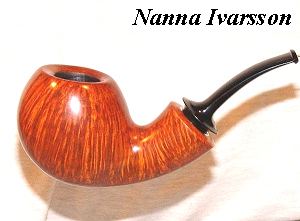

Lars

has a very talented daughter,

Nanna, who has worked as a pipemaker with granddad

Sixten for several years, but now she has chosen to take an education as

designer and left the pipemaking.

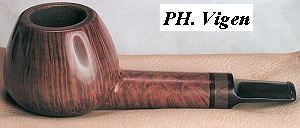

Ph. Vigen

Jes Phillip Vigen Gertsen (artistic name: Ph. Vigen) is one of Denmark’s relatively unknown high grade pipemakers. In

long periods he has made individual pipe maker pipes for other names, including

today. He is presently making the top line of Bjarne pipes in his southern

Denmark based rural work shop. Born in ’53 he started to work in W.Ø. Larsen

work shop with Former as his primary teacher.

When the Larsen work shop closed Ph. Vigen had to find work elsewhere and Svend

Bang, who felt a strong demand for the S. Bang pipes, hired him to work with Ulf

and Per. It didn’t really work out. So after 1½ years he was employed by Pipe

Dan to work in there work shop after Tom Eltang.

His

primary job in Pipe Dan’s work shop was to do all the pipe repairs, but he

also made 8-10 pipes every month. These pipes were – typical to Pipe Dan –

stamped with Ph. Vigens own name and the name of the shop. He stayed with Pipe

Dan until the shop closed in 1991. After Pipe Dan he tried to establish him self

as independent, individual pipemaker, but this was a quite tough period with

declining demand for high grade pipes on many markets.

Any copying, publication or reproduction of the papers and / or pictures published herein in printed or electronic media is strictly prohibited without the explicit written consent of these pages' owner. (c) Pipendoge, 2009

With kind permission of the copyright´s owners